Best Overview to Preventing Weld Undercut: Tips and Techniques

Best Overview to Preventing Weld Undercut: Tips and Techniques

Blog Article

Understanding the Causes and Solutions for Undercut Welding in Metal Construction Procedures

In the world of steel construction procedures, the incident of undercut welding positions a substantial challenge that requires a comprehensive understanding of its reasons and viable options. The intricate interaction of numerous variables during welding operations can lead to this unfavorable phenomenon, impacting the architectural stability and overall quality of the bonded joints - Preventing weld undercut. By exploring the root causes of undercut welding and discovering efficient restorative steps, makers can raise the standard of their craftsmanship and make sure the production of flawless metal components

Usual Root Causes Of Undercut Welding

Frequently forgotten in metal construction, undercut welding happens due to different factors that demand thorough interest and expertise to be successfully alleviated. Additionally, improper welding methods, such as utilizing the wrong welding angle or take a trip speed, can additionally contribute to damage formation. The option of welding specifications, such as voltage, existing, and wire feed rate, plays a significant function in the event of undercut welding.

Impact of Incorrect Welding Parameters

Unreliable welding criteria can substantially compromise the stability and quality of bonded joints in steel manufacture procedures. The effect of incorrect welding parameters shows up in different methods, leading to architectural weak points and flaws in the welded components. Meticulous interest to welding parameters is critical to make sure the production of top notch welds with the desired mechanical residential properties and architectural integrity.

Effect of Improper Torch Angle

Improper lantern angle in welding procedures can considerably affect the quality and honesty of the final weld joints in steel construction procedures. Undercutting is a common welding problem where a groove forms along the weld toe, compromising the joint and jeopardizing its architectural stability.

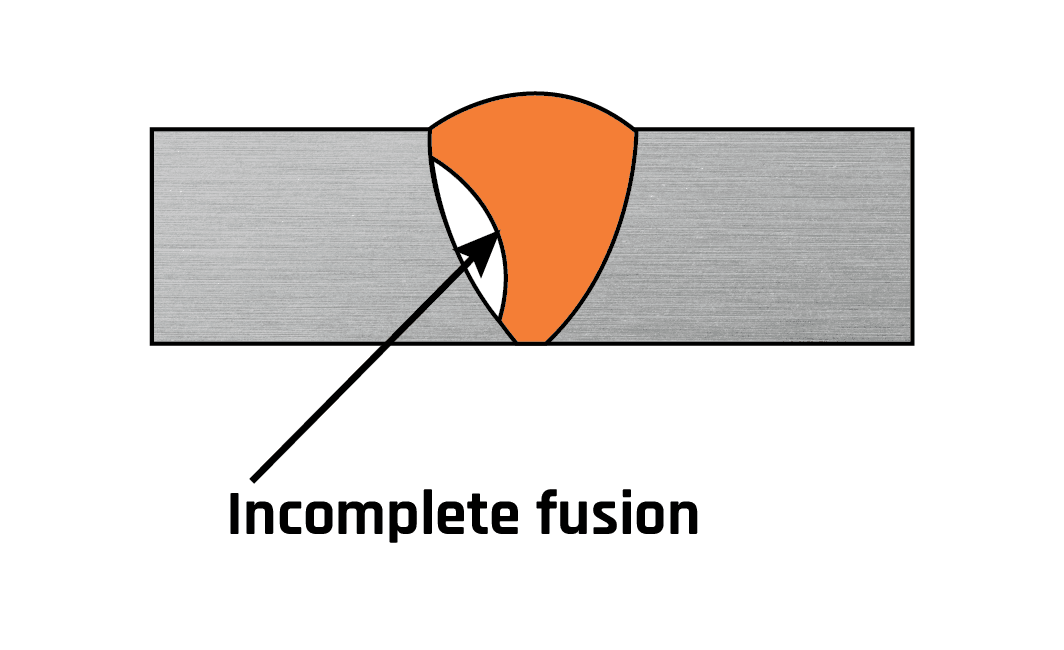

A lantern angle that is as well steep can lead to inadequate penetration, incomplete combination, and enhanced spatter. On the other hand, a torch angle that is too superficial can result in extreme penetration, burn-through, and distortion of the base product. Preventing weld undercut. Correct torch angle is crucial for making certain consistent weld top quality, toughness, and look

To protect against undercutting and other flaws triggered by inappropriate lantern angles, welders need to be trained to preserve the proper torch angle throughout the welding procedure. Normal surveillance and change of torch angles throughout welding can aid accomplish audio welds with minimal flaws.

Duty of Inadequate Welding Methods

An additional aspect of inadequate welding methods is incorrect weld preparation. Poor cleaning of the base metals, incorrect joint style, or inadequate edge prep work can all contribute to damage welding. In addition, inadequate shielding gas protection or utilizing the wrong kind of gas can lead to insufficient combination and the formation of undercut defects.

To address the function of company website inadequate welding strategies in steel fabrication procedures, it is important to offer comprehensive training for welders. Correct education on welding specifications, joint prep work, and securing gas option can aid protect against undercut welding and guarantee top notch welds in steel construction jobs.

Reliable Solutions for Undercut Welding

Addressing undercut welding in metal fabrication requires carrying out efficient solutions to boost weld top quality and architectural honesty. One of the main services to fight undercut is to change welding criteria such as voltage, existing, and take a trip rate to guarantee correct heat input and fusion. By fine-tuning these settings, welders can protect against too much melting of the base metal and filler material, minimizing the possibility of undercut development.

In addition, appropriate joint prep work is important in protecting against undercut. Ensuring tidy base steel surfaces devoid of impurities and utilizing the ideal bevel angle can help promote better weld infiltration and lower the threat of undercut - Preventing weld undercut. Employing ideal welding strategies, such as weaving or oscillating the torch, can also help in distributing warmth equally and filling the weld joint effectively, reducing the possibility of undercut issues

Additionally, choosing the appropriate welding consumables, including electrodes and filler steels, is essential in alleviating undercut. Utilizing materials with suitable chemical compositions and mechanical residential or commercial properties can add to accomplishing sound welds with marginal undercut. Normal inspection and top quality control procedures need to additionally be carried out to detect and deal with undercut concerns without delay, ensuring the total honesty of made metal parts.

Final Thought

In final thought, recognizing the reasons and remedies for undercut welding in steel construction processes is vital for attaining high-quality welds. By resolving typical causes such as why not look here inaccurate welding parameters, inappropriate torch angle, and insufficient welding strategies, welders can protect against click this link damaging and ensure strong, resilient welds. It is vital to focus on these factors and execute reliable options to improve the general welding process and final item high quality.

Report this page